Furnace Equipment

Delivery program

Heattec’s delivery program includes oven installations for the food industry, glass industry, metal industry, plastic industry, powder coating industry and belt dryers for various drying processes.

Food industry

- Electric and gas-fired infrared continuous furnaces for baking, grilling and cooking of food products.

- Electric and gas-fired hot air furnaces for drying, baking and cooking of food products.

- Boilers for breweries.

Glass industry

- Gas or electrically fired infrared glass bending kilns

- Glass annealing and heat soaking furnaces for the heat soaking of different kinds of glass products

- Glass melting kilns

- Glass decoration furnaces

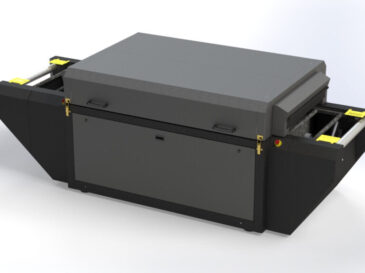

- Foil lamination furnaces for the vacuum lamination of glass panels and drying cabinets for the dry storage of lamination foil

- Die pre-heaters.

Standard types of gas fired infrared glass bending kilns |

||||||

| Inside dimensions* | Gasconsumption | |||||

| Type | Width (mm) | Length (mm) | Height (mm) | Capacity (kW) | Natural gas (m3/u) | Propane gas (kg/u) |

| GL 15.15 | 1500 | 1500 | 400/600/800 | 58 | 6,3 | 4,2 |

| GL 15.20 | 1500 | 2000 | 400/600/800 | 78 | 8,4 | 5,6 |

| GL 15.25 | 1500 | 2500 | 400/600/800 | 97 | 10,5 | 7,0 |

| GL 15.30 | 1500 | 3000 | 400/600/800 | 117 | 12,5 | 8,4 |

| GL 20.30 | 2000 | 3000 | 400/600/800 | 156 | 17,0 | 11,2 |

| GL 25.40 | 2500 | 4000 | 400/600/800 | 260 | 28,0 | 19,0 |

| GL 30.40 | 3000 | 4000 | 400/600/800 | 312 | 33,5 | 22,5 |

| * Other sizes also available | ||||||

Metal industry

- Gas or electric fired chamber-, pit-, hat-, and bogie hearth furnaces for all kinds of processes such as nitriding, carburising, bright annealing etc.

- Gas or electric fired paint curing ovens for drying, curing and preserving metals, plastics and composite materials.

- Die pre-heating furnaces for the aluminium industry

- Al-aging furnaces for the aluminium industry

- Salt bath furnaces

- Pyrolyse furnaces and thermal cleaning furnaces

- Industrial drying furnaces for drying of varnishes, solvents and moisture

- Walking beam furnaces for forging, tempering, etc.

- Melting kilns for melting of bronze, cast-iron or aluminium

- Gas fired furnace installations for preservation heat treatment of steel plates and steel profiles.

Plastic industry

- Furnace installations for the curing of fibre reinforced resin products

- Infrared burner systems for thermo shaping of plastic products

- Aging Ovens.

- Infrared burner panels for the thermoforming of plastic materials.

Ceramic industry

Heattec designs and manufactures tunnel dryers that can be used to dry ink in digital printing, screen printing and transfer printing on textiles, glass, porcelain and metal. The tunnel dryers can also be used for other heat treatment processes up to 250°C.

Heattec’s delivery package does not end with furnace installations for the above industries and applications. We also have a wide variety of furnace, burner and/or flare installations for specific processes in our package. Our strength lies in providing customized solutions. Need advice or are you having questions? Feel free to contact us via the button below.